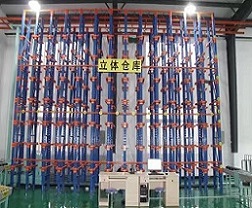

BL-TH intelligent warehouse |

Thank you very much for choosing the EU CE member BaoLai

BL-TH intelligent warehouse

1. Standard configuration and advantages

1) High shelf storage: save storage floor space and improve space utilization. At present, the height of the highest stereoscopic warehouse has reached 50m, and the storage capacity per unit area can reach 7.5t/m?, It is 5-6 times that of ordinary warehouse.

2) Automatic access: stacker, roller line, stacker With the cooperation of the stacking robot, the operation and processing speed are fast, and at the same time, it can be conveniently incorporated into the enterprise's material system.

3) Computer control: easy to count and inventory, and reduce inventory reasonably.

2. Intelligent warehouse function

1) Receiving: The warehouse receives various materials/semi-finished products/finished products from suppliers or workshops for production or processing and assembly.

2) Inventory: The unloaded goods are stored in the position specified by the automation system.

3) Picking up: get the goods required by customers from the warehouse according to the demand. First in first out (FIFO) mode is usually adopted.

4) Delivery: deliver the goods to customers according to strict requirements.

5) Information query: It can query relevant information of the warehouse at any time, including inventory information, operation information and other information.

3. Features of intelligent warehouse

1) Structurally, it can be divided into single column stacker and double column stacker.

2) It can be divided into single extension stacker and double extension stacker according to different picking methods.

3) The stacker can be used together with the shelf. The Z height can reach 50 meters. The running rails can be straight rails, curved rails and fork rails.

4) Laser and barcode positioning are adopted for the positioning of the stacker to ensure its accuracy.

5) Closed loop frequency conversion speed regulation or servo motor is adopted for speed control to ensure stable and safe transmission.

6) The safety protection of the stacker adopts both electrical and mechanical protection, such as mechanical stop, safety gear, torque limiter, emergency stop switch, speed limiter, chain (rope) break protection, etc.

7) In order to ensure its safety performance, all electrical components of the stacker are made of high-quality imported brand products.

4. Intelligent warehouse selection

1) Self propelled trolley dispatching system (AGV): responsible for the trolley's running direction, speed, charging, multi vehicle cooperation, etc.

2) Production Management System (MES): It is responsible for managing the production of the entire production enterprise. The warehousing logistics is only a part of the production management system.

Science and technology create a better future